At the very end of 2008, I was approached by Super Talent Technology (a producer of DRAM and flash memory products for the PC and consumer electronics market) and was asked to put together a display system for their booth at the upcoming Consumer Electronics Show (CES) in Las Vegas, Nevada. Not everything about the arrangement was particularly rosy, though, as I ended up shelling out somewhere in the ballpark of $300-$400 for cooling parts, modding supplies, and custom appliqués in exchange for permission to put the store's URL on the case (and, no, I didn't get to keep the system). To top it all off, I had maybe two weeks to order all of the parts necessary, build the system, and haul it off to Las Vegas while still running the store and dealing with all of the personal stuff that was going on--to do this sort of project "right" I'd usually ask for

at least six to eight weeks. Total forum thread views: 11,083 (as of 5/05/2010) and the original thread can be found

here. As a side note, all images have been re-sized via HTML, rather than my usual two image (preview & full image via link) approach, to speed along the archiving process. You can still right-click on the images and view them at full-size in a new tab/window. Also note that all vBulletin emoticons and their associated code have been removed from the archive entry.

!--Start of Archive--!

[Entry 1]

I usually don't post worklogs... mostly because I'm too busy actually modding but I figure that I probably should for this one (even though it isn't really a "major" mod at all).

Anyway, last week (or perhaps the week before... I really can't remember) I was contacted by Super Talent Technologies (they do memory) to put together a display machine for their CES booth. Frankly, it's a little late in the year to be asking for custom display machines but, whatever, I'm game.

They dropped off the goodies on some Friday (was either last Friday or the Friday prior) and I've spent time collecting other parts, getting custom appliqués on order, and prepping stuff. Now, the catch with this build is that I get to foot the bill for all modding-related stuffs, water cooling, and appliqués. In exchange, I can put our logo and stuff on the case.

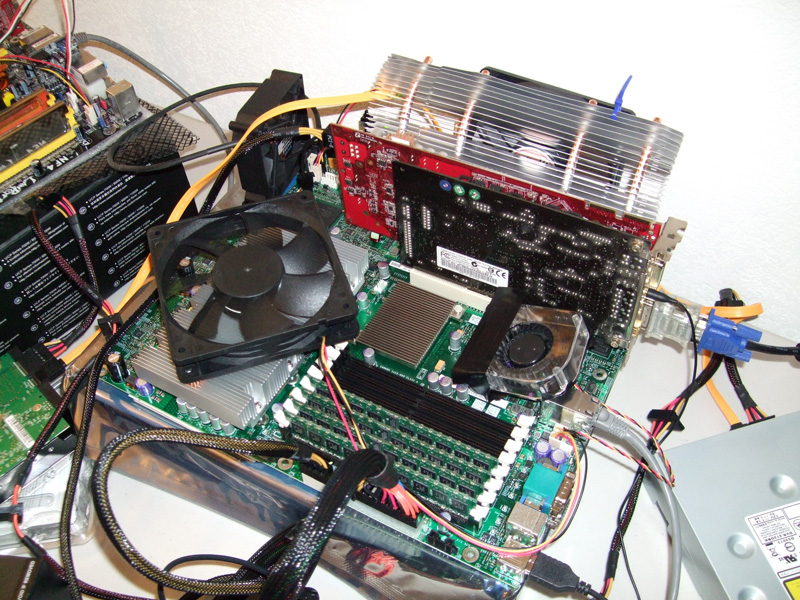

What Super Talent dropped off:

Aside from the Antec 900, not too shabby.

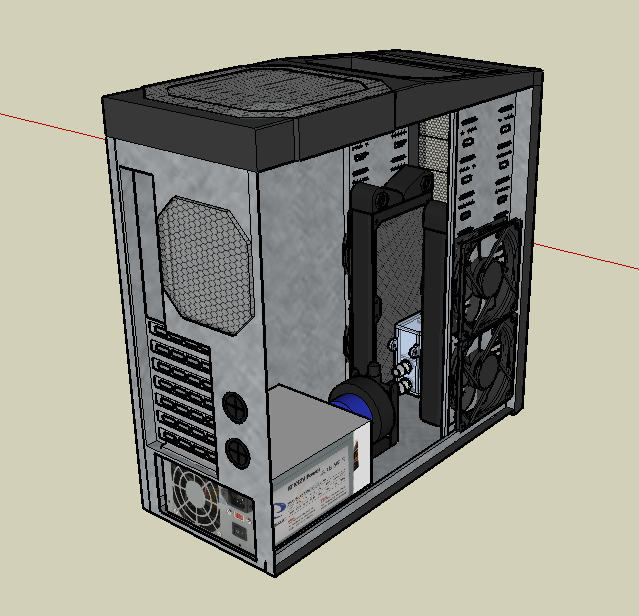

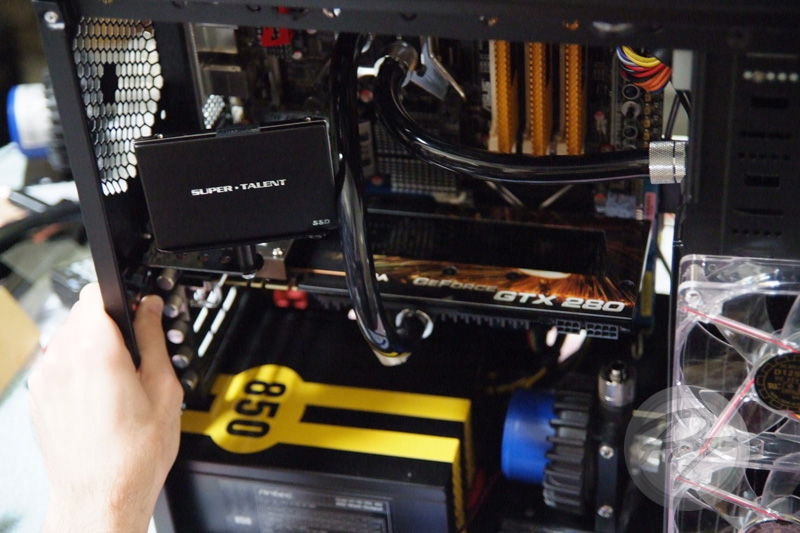

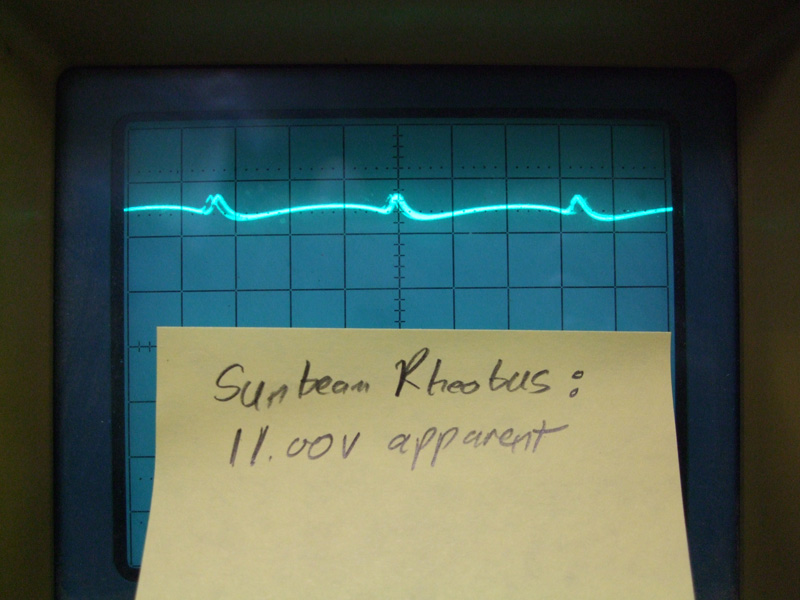

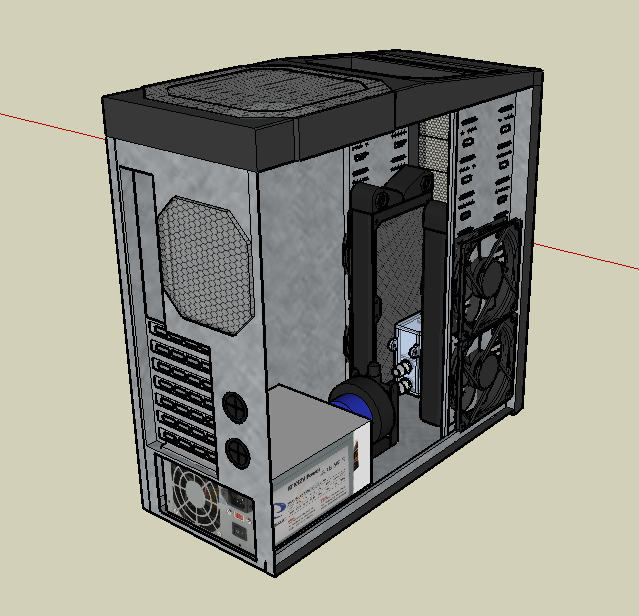

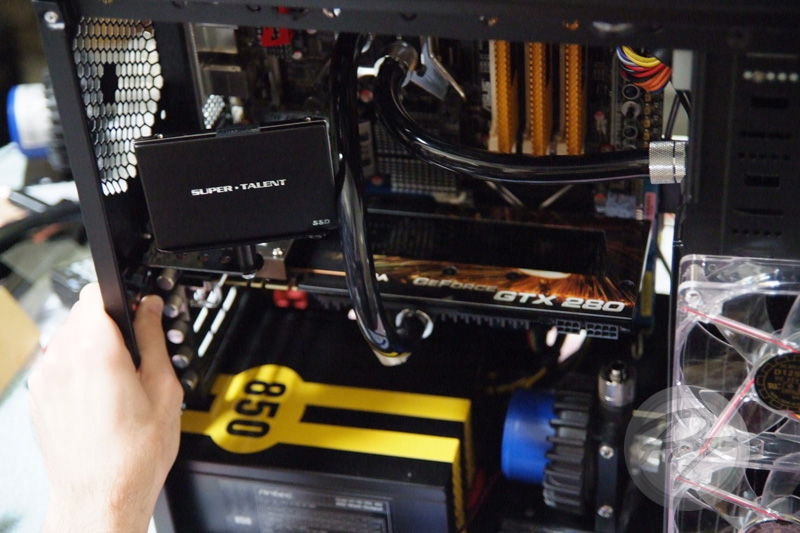

The two main items that I need to focus on 'showcasing' are the solid state drive and the 3GB DDR3 kit. I'm thinking that I'll work up some sort of bracket to mount the SSD up near a case window or something. Aside from that, I've mostly just been thinking about cooling (then again, when am I not?) and mucking about in Sketchup to see what'll fit and what won't.

Dual MCR220's, modded drive cages, some flat black interior paint, white LED fans, a custom cut window, black tubing, compressions, and stainless radgrilles on the side panels acting as exhausts for the radiators is the current plan... with the two main issues being mounting the radiators and getting ahold of an extra right-side (blank) panel for the 900. I can't get particularly wild with this build not only because I don't have the time to do so, but also because they want the case easily transportable/shippable (so, no external craziness).

Cutting should commence tomorrow.

Would anyone in the bay area happen to have a spare Antec 900 side panel?

[/Entry 1]

[Entry 2]

Sorry for the lack of updates, but I've been busy juggling this project, the store, and personal stuff.

Anyway, I leave for CES in two days... and, boy, do I have my work cut out for me.

Here's a quick summary of where I'm at and how I got there:

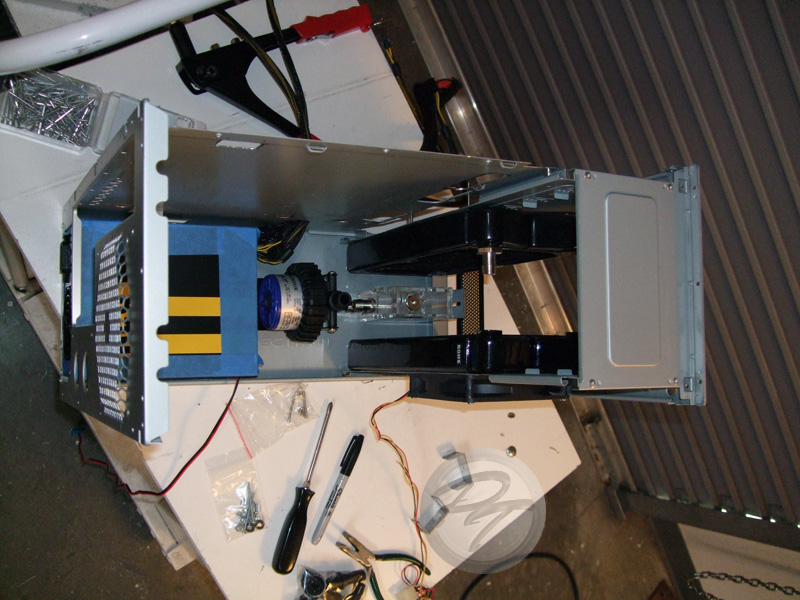

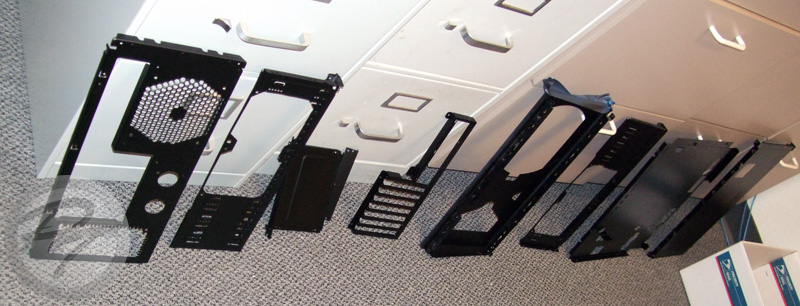

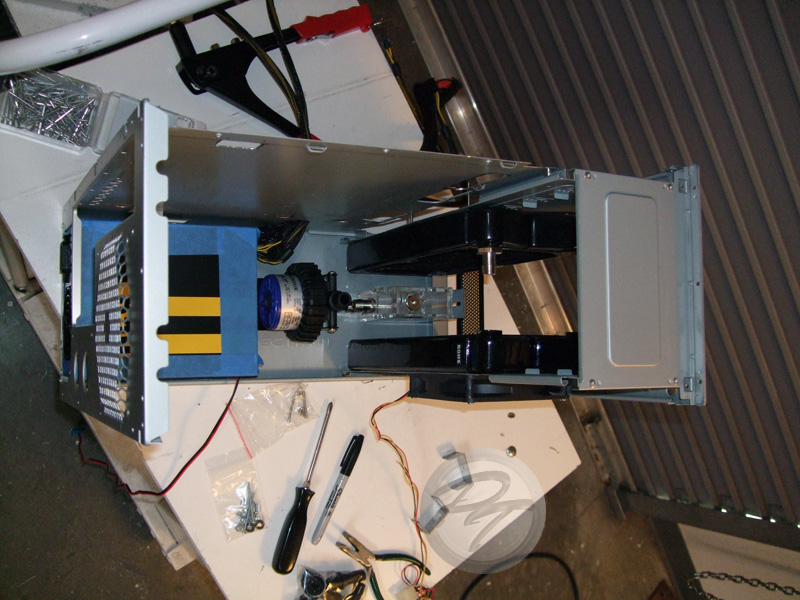

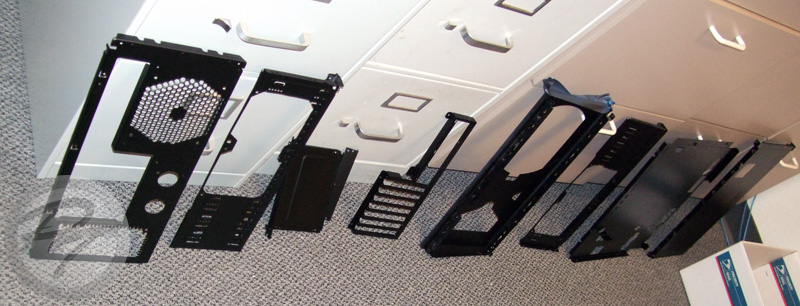

Started by stripping the case (pulling all the cages, covers, and other crap out).

A little blue painter's tape on the PSU so as not to scratch it up while test fitting stuff.

Marking up the case to act as a guide for the primary cuts. I'm very much a hands-on, throw stuff in, figure out where to cut, go crazy with Sharpie kind of modder who's projects tend to change as I move through them--it's fun!

...and the carnage begins! Before anyone asks, yes, I'm wearing both safety glasses and earplugs (otherwise, I would have become blind and deaf long ago). What the picture can't show you, though, are my poor Logitech Z-2300's blasting away in the background (a mix of Muse, Led Zeppelin, and Audioslave, in case anyone is curious).

By this point, I'm starting to drill the rivets out of the case to take it apart so that I can finish most of the cutting.

Whadda 'ya know... it's back together again. After pulling the case entirely apart and cutting it up some more, I partially reassembled it so that I could test fit some of the components and check for any additional modifications that it needed. All that excess Sharpie really makes the cuts look a lot worse than they actually are...

Looking familiar?

I'm also using the opportunity to mark spots where mounting holes will be needed and figure out the SSD mount (not shown).

Turns out that a few more mm had to be trimmed from the motherboard tray so that I could mount fans up to the radiator on the right... Eh, at least I was close on the first go.

Which brings us to today...

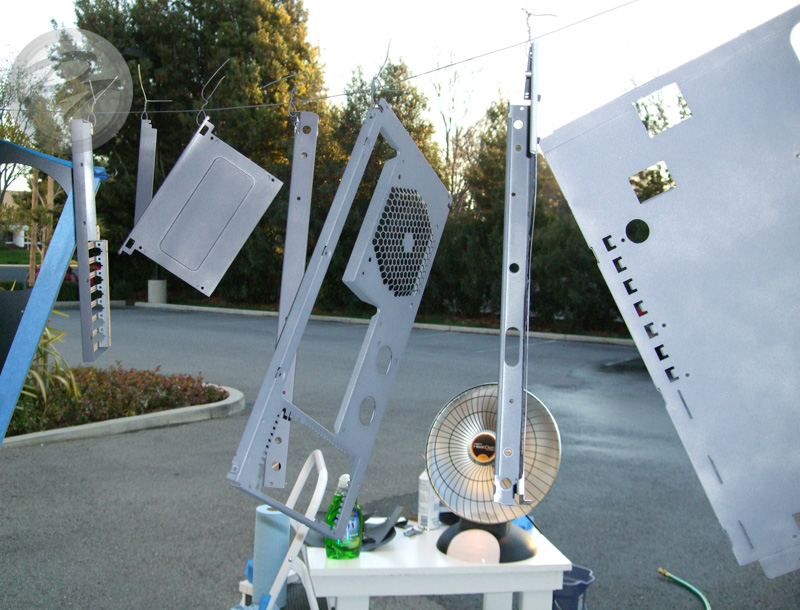

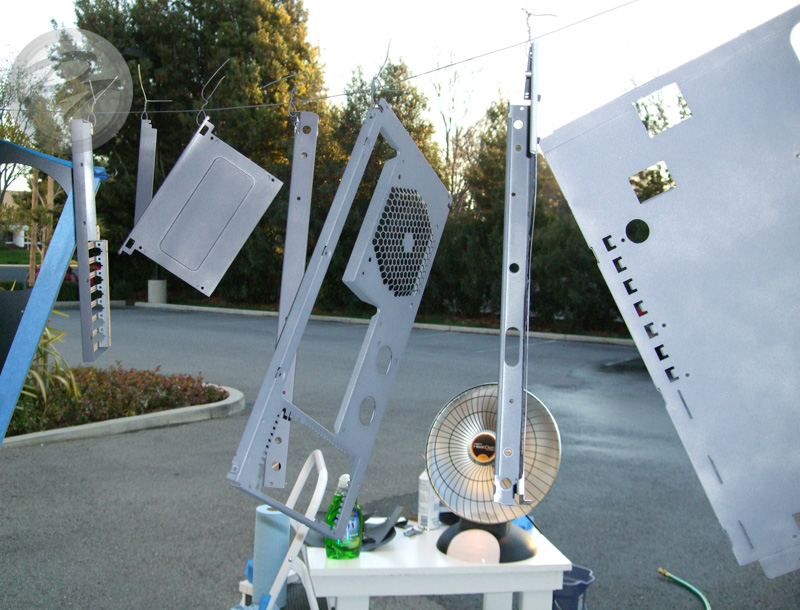

Here the case has been disassembled

again, each panel deburred, filed, wet sanded, thoroughly cleaned, and hung for priming.

It started getting quite cold, so out came the dish heater to keep the panels warm (paint was stored in the front office, so I didn't have to worry about warming it).

Finished priming and allowing things to dry for an hour before rushing into a color coat. I really don't like rushing paint because it's just one of those things that, if you take the time to do it right, can make the difference between an amazing mod and a mediocre mod... but, with so little time to work with, I obviously can't spend weeks on paint (which is why I'm not even considering external paint).

Applying color coats to the panels... in the dark.... with only the dish to keep the parts warm and cure the paint (probably about 45°F out by this point).

After things cured enough to be carefully handled, I moved all of the panels into the office and programmed the thermostat to hold the temperature at 75°F all night to help the paint cure (by the time I left, the temperature in the warehouse was lingering around 40°F... not a great environment for paint to cure quickly). The sad part is that it takes a full week for this paint to completely cure, so it won't actually be done until after CES is over... but that won't stop me from finishing the case anyway!

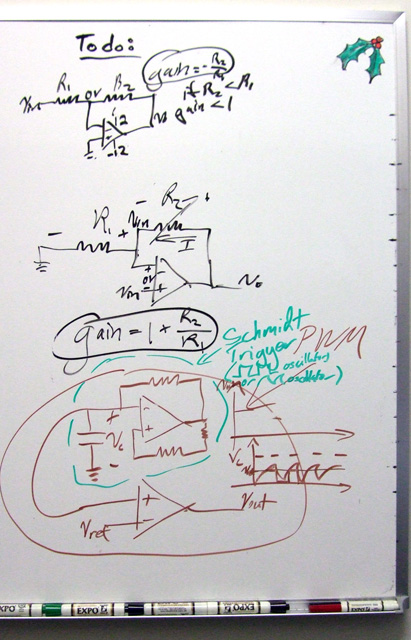

So, my 'to do' list for tomorrow (Monday) consists of the following:

- Cut the side panels (window for the left panel and one 'radgrill' hole for each side).

- Deburr, wet sand, clean, prime, and paint the insides of the side panels.

- Pop rivet the chassis back together.

- Start assembling computer.

- Pray all of the parts work (I haven't had time to test

any of the components that Super Talent dropped off).

Tuesday's list should go like this:

- Finish assembling computer.

- Fill water cooling system.

- Install Windows.

- Apply the custom Appliqués which should arrive on Monday (despite a few setbacks, Terry over at Shatteredweb has been great to work with, as always).

- Box the system up, stuff it into the 328i (since there's no way it's fitting in the roadster), and start the first leg of my drive to Vegas (breaking it into two days because I have to drop by SLO to deliver a TV).

Time for sleep....

[/Entry 2]

[Entry 3]

Well, I worked late into the night last night (like every night for nearly the past week) and am almost done... should be able to finish everything up today. Sadly, there's no way I'll be able to make it to Vegas for the opening day of CES (because I'm driving, the best I'll be able to do is Thursday evening). I've had to take a lot of shortcuts and make a lot of compromises to get this thing done and I'm not very happy about that, but it'll still look pretty cool (just not up to my usual standards).

Pictures will be posted if I have time... otherwise you'll either have to go to Sands Convention Center booth #72421 or wait 'till Sunday to see it.

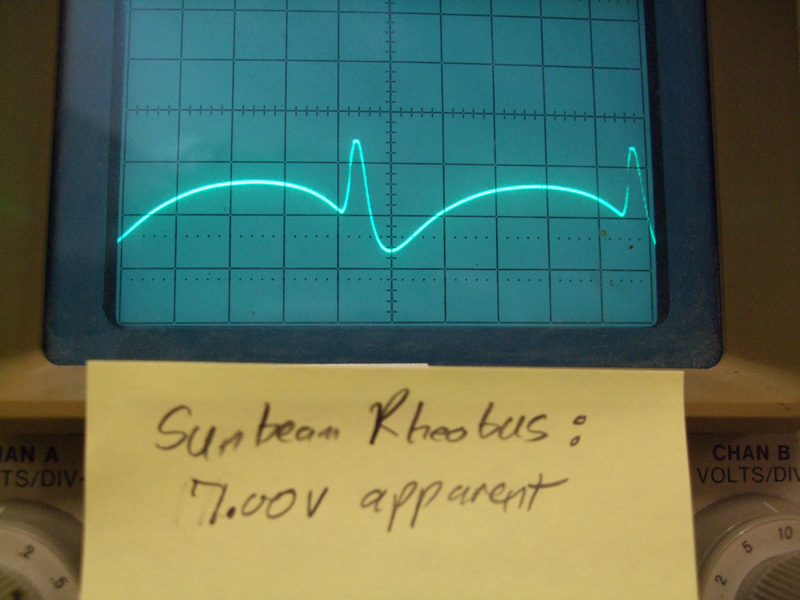

As a side note... Dave, your pump brackets are too damn strong ;-)

[/Entry 3]

[Entry 4]

Okay, okay... I just finished sifting through photos and resizing stuff last night, so here we go!

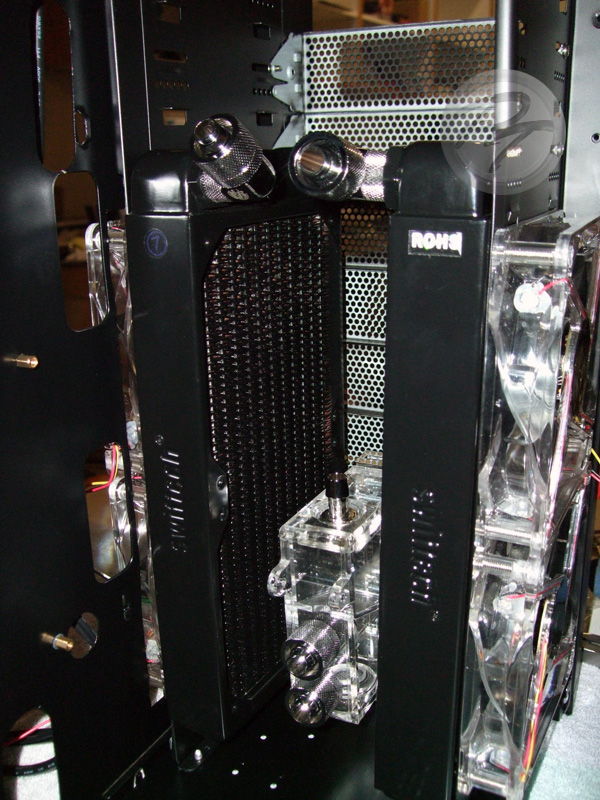

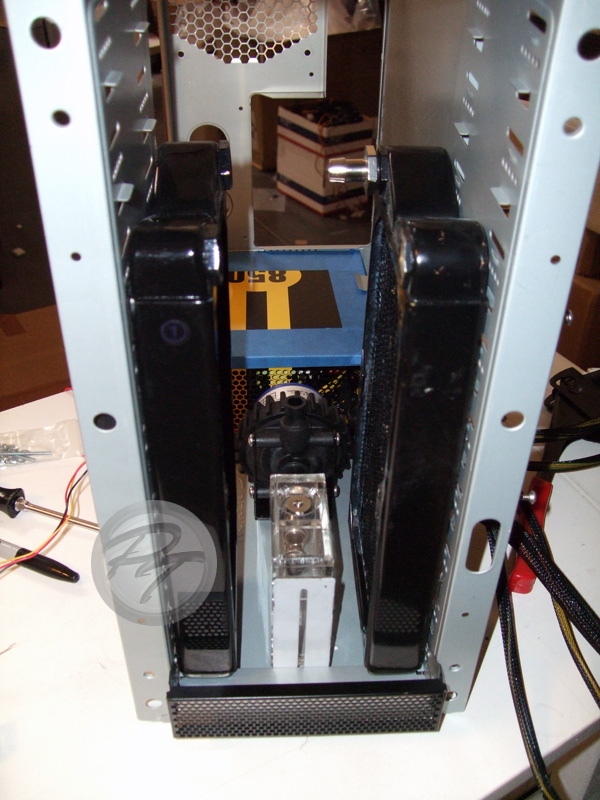

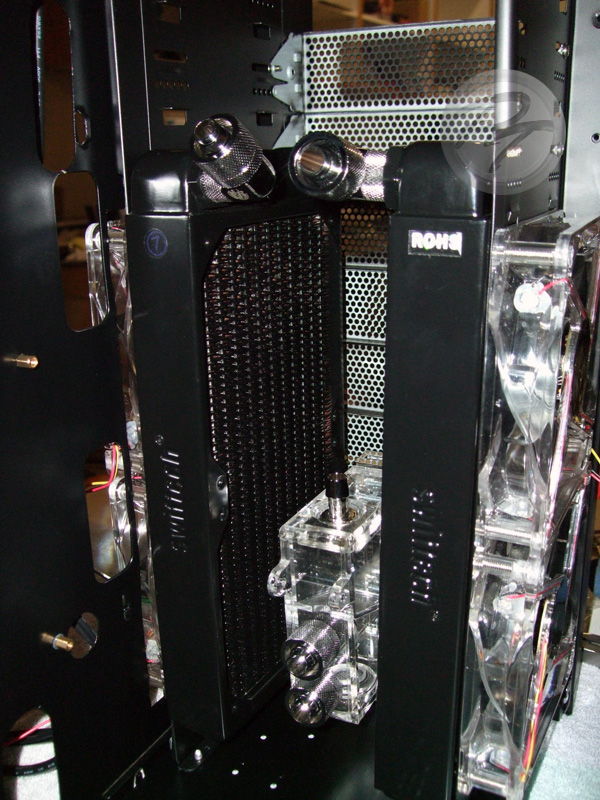

After getting the chassis riveted back together...

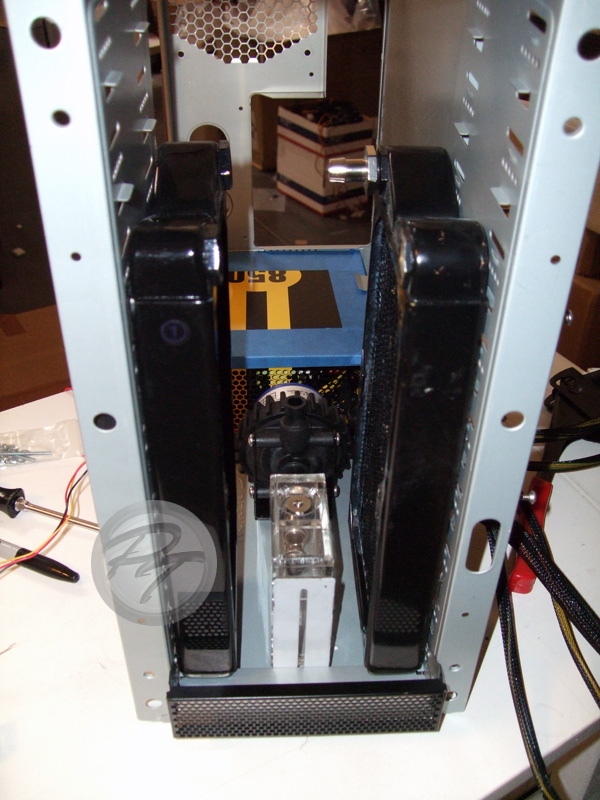

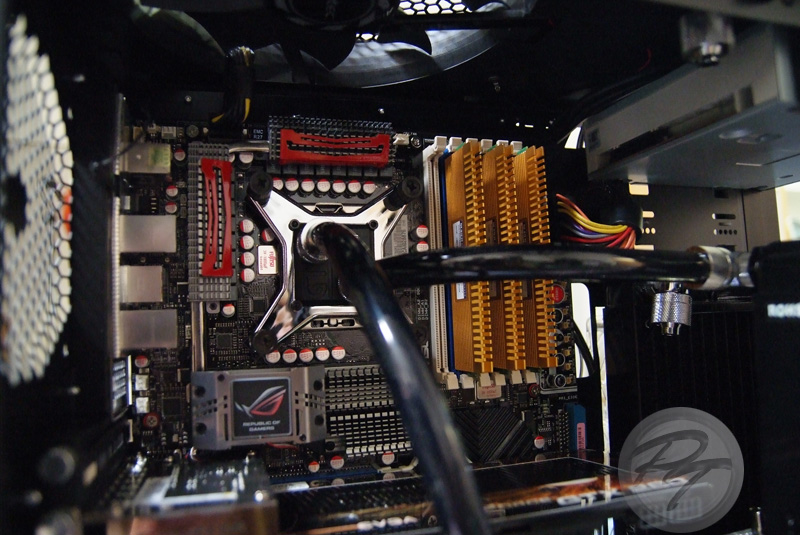

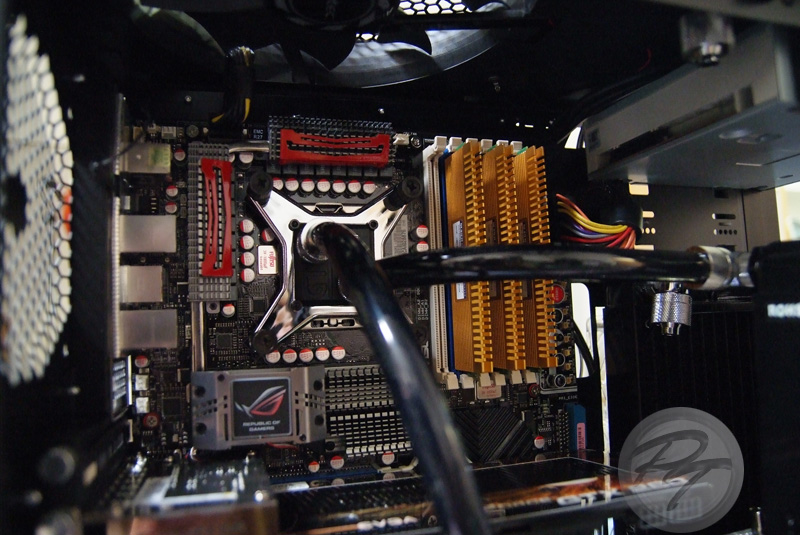

Checking radiator and reservoir fitment...

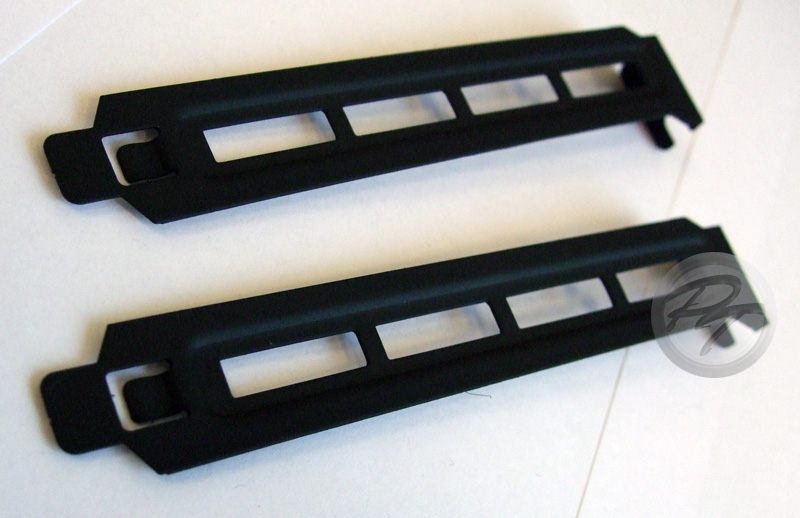

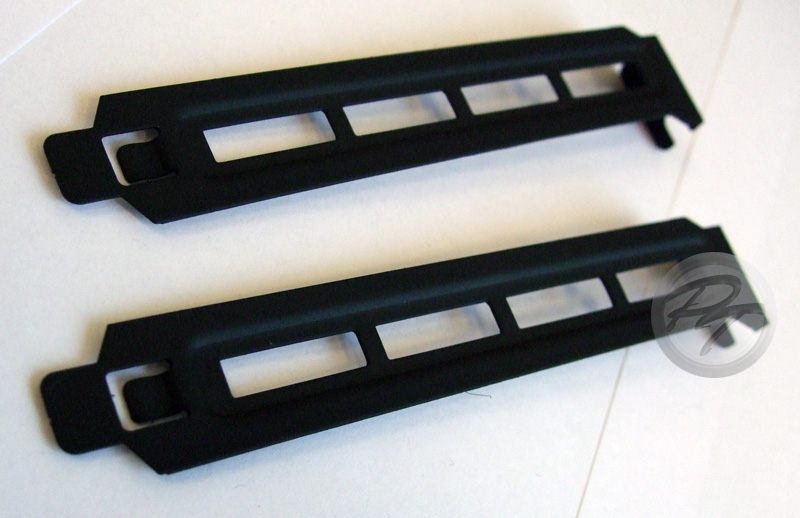

A quick spray and cook of the PCI bracket covers... That dish heater really comes in handy (even if the color and finish are a little different as a result.

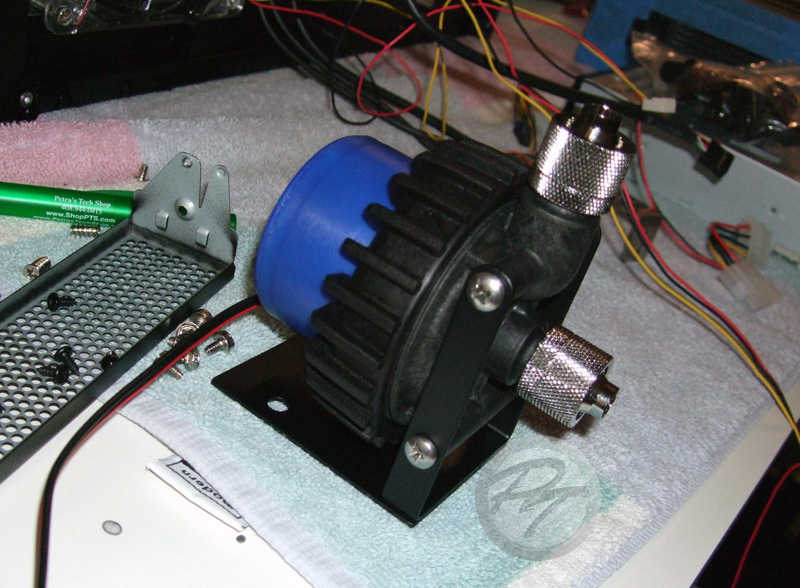

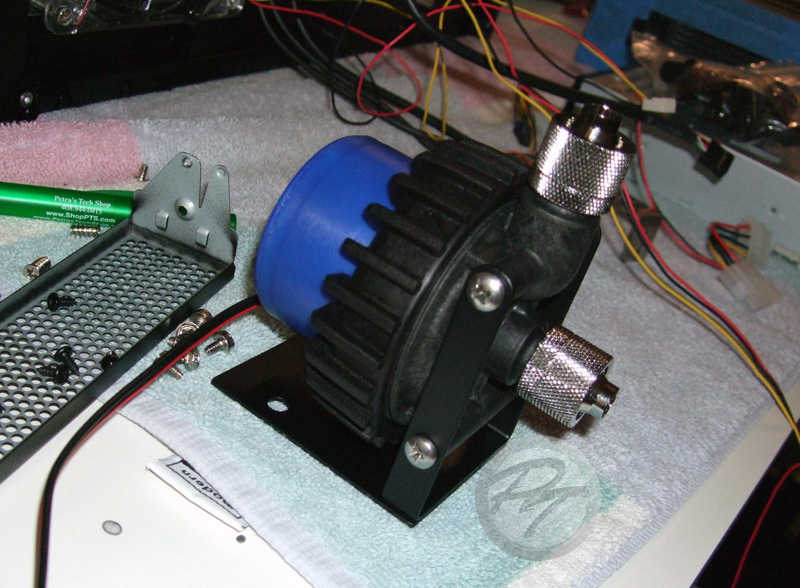

A little cutting, filing, sanding, tapping and... voila! Compression fitting equipped, G1/4 tapped D4.

Prior to the fitting of tubing.

Bleeding the loop...

Installing Windows

Now some shots from the Super Talent booth at CES... as you can tell, I kept having problems with sagging window molding through the show because I just didn't have time to tack the molding down before leaving for Vegas. Heck, I was still applying appliqués on the show floor.

...and this one's just for you, Dave:

Oliver ( Fr3ak ) has some more photos from the CES floor.

[/Entry 4]

[Entry 5]

"Very nice and clean look. Only 1 thing i don't like :P Paint that Dvd-rom inside of case :P" -Borys

Oh, there are a ton of little things that bother me about this build... the unpainted DVD-ROM, unpainted internals of the 5.25" bay covers, didn't have time to paint the insides of the two side panels (not that you really see them), the window molding (and the fact that I had to use it), not having time to paint the exterior (deep, gloss black with lots of clear would have been nice), wiring could have been nicer, didn't have time to sleeve stuff, the cuts could have been better and could have used more clean-up... the list goes on and on... I'm my own worst critic.

Still looks good, though :-)

"How are the actual temps on the system? I am thinking of doing this on my TT armor with a 3x120 on one side and 2x120 in the top." -Camaroz06

Ya know, I can't really recall... Honestly, I put it together, checked the temps to make sure that everything was working alright, and moved on to more assembly. As for what you're planning, a triple and a dual fan radiator should be more than enough to handle an i7 system with a couple video cards.

"Excellent build. Sorry I did not make it to the Sands and sorry I did not see you at the XS party." -DarthBeavis

Thanks :-)

I wasn't able to get away from everyone at CES early enough to meet up with many at the XS party (I think that I got there at like 8:30 or 9:00pm... but was there until like 3:00am). There's always next year!

"Very nice! It'd be nice to get to build rigs for free." -atomic ferret

Free? Hah... I ended up putting over $100 in fittings alone into that case (not to mention all of the cooling gear, paint, appliqués, and modding supplies)... and I didn't even get to keep it :-(

"In a more productive note petra do is there a version of the Antec 900 without a case window because all the ones I'm seeing have a case window already built in that funky shape." -silverphoenix

Nope but the side panels are interchangeable and Antec sells the blank panel on their website. I ended up stealing a panel from some guy's home system (has a 900, works for Super Talent, offered it up so that I could finish in time for the show).

[/Entry 5]

!--End of Archive--!